Kanemoto Shokai Co., Ltd.

|

Producing RPF (solid fuel) from waste to create clean energy |

Targets

7.1 By 2030, ensure universal access to affordable, reliable and modern energy services

7.2 By 2030, increase substantially the share of renewable energy in the global energy mix

7.3 By 2030, double the global rate of improvement in energy efficiency

12.2 By 2030, achieve the sustainable management and efficient use of natural resources

12.5 By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse

Initiative details

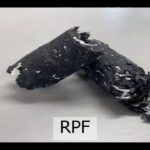

We produce about 1,600 tons of solid fuel (RPF) per year from waste produced by factories and other sources. RPF is a high-grade fuel that produces approximately 33% less CO2 emissions than coal.

To produce RPF, the procured waste is first crushed into pieces of less than 5 cm in size. For this work, two large German-made crushers are used to increase the efficiency of the process. The RPF is then formed by heating the crushed waste to solidify it.

RPF-1024x768.jpg)

The RPF that we produce is shipped to major paper companies, major chemical manufacturers, and poultry farms, where it is used in boilers for power generation as an alternative to coal.

The use of RPF as an alternative to coal is a very environmentally friendly measure as it reduces CO2 emissions, saves exhaustible resources, and generates synergistic effects such as extending the life of landfill sites. The residue left in the boiler after combustion can be reused as roadbed material, etc., further contributing to the effective use of resources.

In this way, our RPF production business is making a significant contribution to reducing the use of fossil fuels and the amount of waste sent to landfills.

廃棄物処理-1024x768.jpg)

Key Points

By making proposals to manufacturers for the conversion of their waste into RPF and implementing them, we help them take responsibility for their production and consumption.

In addition, we have installed waste containers at manufacturers (mainly automobile suppliers) in Hiroshima Prefecture. The waste plastics from these containers, which are used as the raw material for RPF, are collected daily and converted into RPF at our plant.

To transport the RPF we produce, we use our own large trailer that can carry about 23 tons at a time, reducing the number of runs we have to make and helping minimize CO2 emissions in this respect too.

空撮-1024x695.jpg)

Kanemoto Shokai Co., Ltd.

9-1-23 Kabe Asakita-Ku, Hiroshima

+81-082-818-4385

Tags associated with this article