Hiroshima Eagle Co., Ltd. (Students’ report on the SDGs)

|

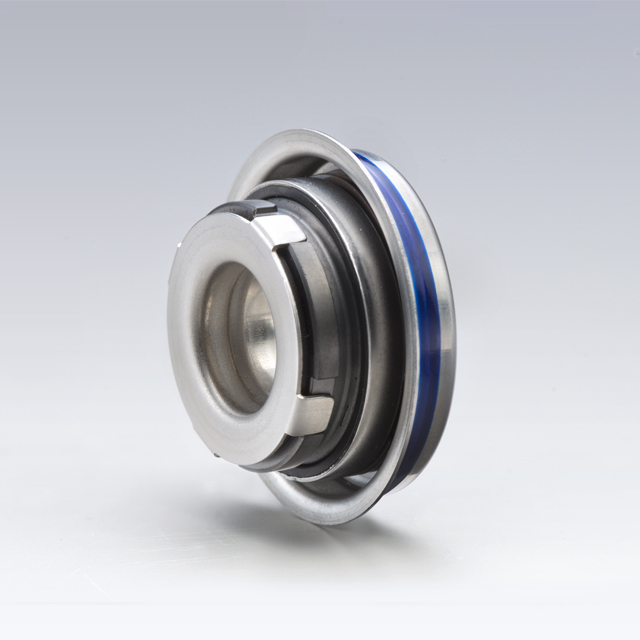

Delivering products that consider environmental issues

Hiroshima Eagle Co., Ltd., established in 2009, manufactures and supplies mechanical seals and other parts used in automobiles. Mechanical seals are a type of packing installed on the power transmitting shaft of a rotating machine, preventing the leakage of cooling water. The company also manufactures environmentally friendly parts, such as control valves (*1), which contribute to lower fuel consumption, and lip seals (*2), which prevent CFC gas leakage. From April 2021, it began full-scale implementation of SDGs initiatives, with the goal of “reducing CO2 emissions by 50% by FY2030.”

(*1) Control valve: An operating device used in factories. It enables the adjustment of physical quantities such as flow rate, pressure, temperature, and liquid level, contributing to lower fuel consumption.

(*2) Lip seal: A type of packing. It prevents the leakage of CFC gas, including that contained in refrigerator oil for car air-conditioners.

Aiming for and achieving zero

In order to reduce CO2 emissions, Hiroshima Eagle Co., Ltd. introduced solar power generation and electric vehicles in 2021, and it has reduced CO2 emissions in the current year by 6.5% compared to the previous year. The company also focuses on “Eternal Zero” activities to reduce defective products, and this year marks the sixth year of such activities. By changing the size of the pump that sends out the processed parts, denting and scratching of the parts are prevented, and a machine for visual inspection has been introduced to prevent overlooking of any defective products.

Through this interview, we learned that Hiroshima Eagle Co., Ltd. is contributing to the SDGs by addressing climate change, as well as by eliminating the waste of resources through measures and improvements to tackle the very difficult task of “preventing the release of any defective products.”

Aiming for health and safety across the entire company

Hiroshima Eagle Co., Ltd. is working on health and productivity management with an emphasis on maintaining and improving the health of its employees. In FY2021, the company was certified as a five-star business in the “Hiroshima Corporate Health Declaration, Certificate of Excellence in Health Promotion.”

In addition, the “Eternal Zero” activities mentioned above are not limited to quality, but also extend to initiatives for the mental and physical health of employees. As part of its “Eternal Zero” activities, the company has been working to reduce the number of traffic and occupational accidents among its employees to zero, and the number of such accidents has decreased compared to before the activities were initiated. We think that the company-wide efforts to achieve zero traffic and occupational accidents have led to a positive change in the awareness of individual employees.

We conducted interviews!

OKAWA Kana (2nd year student, Yasuda Women’s University)

SAEKI Riko (1st year student, Hiroshima Shudo University)

Hiroshima Eagle Co., Ltd.

6 Shin-Ujigami, Kitahiroshima-cho, Yamagata-gun

+81-0826-72-5900

https://www.ekkeagle.com/jp/hek/

Tags associated with this article